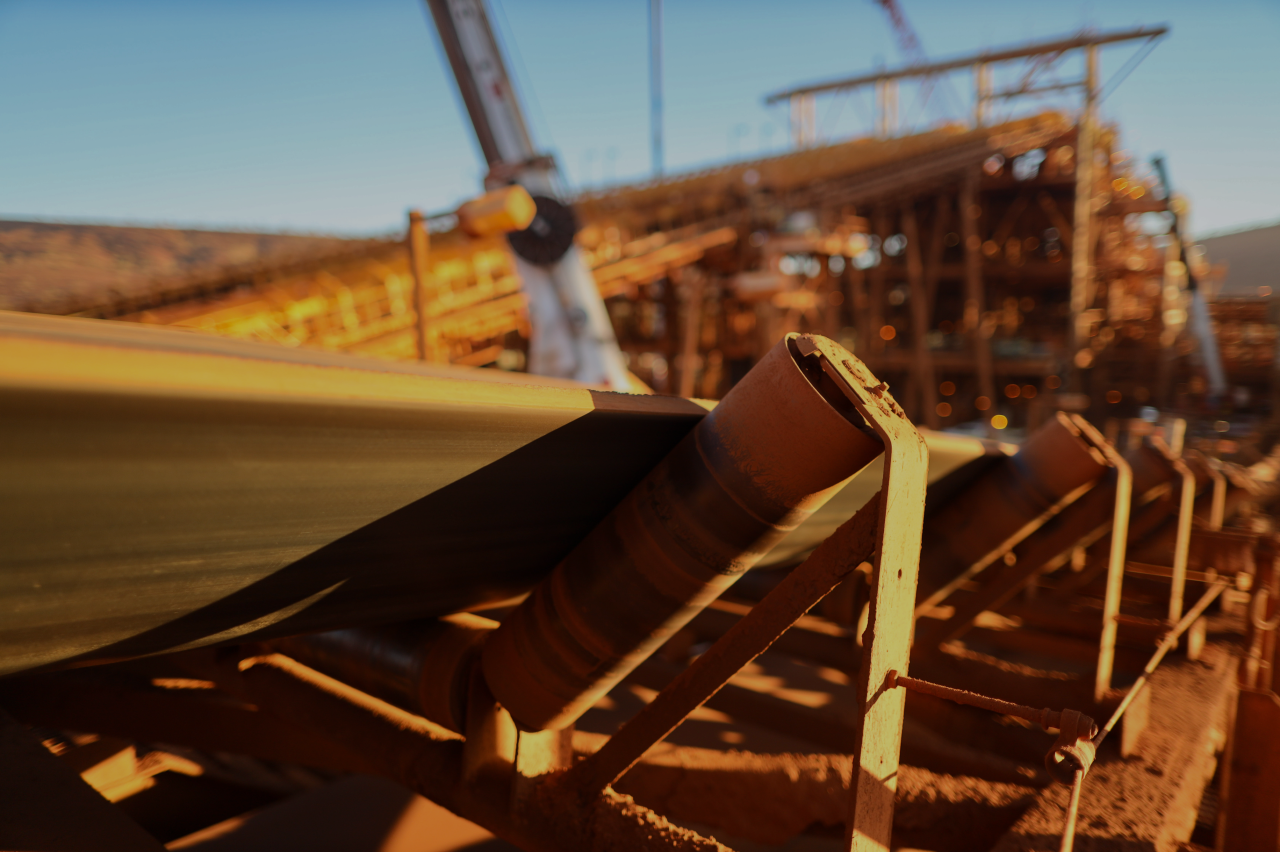

Bulk Materials Handling

Verum Projects are experts in minimising downtime and increasing production through efficient loading, conveying and transport systems in mineral processing plants.

We offer Engineering of Bulk Materials Handling systems, from material characterisation to design, engineering and selection of equipment that best suits your company’s individual requirements. Our designs pursue systems that create a safe plant environment while minimizing spillage and waste.

Following a thorough consultation, Verum Projects will work with you for the best bulk handling solution including bins, hoppers, conveyors and related structures for reliable and durable loading, conveying and transfer of mineral processing bulk materials.

Our expert and comprehensive service ensures that you are utilising the most efficient and productive systems available, within budget.

Existing plant Upgrades

Our services cover upgrades and improvements to existing plants that can maximise your current investment.

Maintenance and Auditing of Bulk Materials Handling Systems

We offer ongoing services such as on-site safety and operational audits, inspections, troubleshooting, debottlenecking, system repair and reconditioning recommendations. We can also provide Safety and Operational Auditing for all your existing Materials Handling Assets.

Standards

The following are some of the design standards and codes that Verum Projects make use of:

- AS1403 Shaft Calculations

- AS1554 Structural Steel Welding

- AS1657 Fixed Platforms, Walkways, Stairways and Ladders

- AS3600 Concrete Structures

- AS4024 Safety of Machines

- AS4100 Steel Structures

- AS/NZS IEC 31010 Risk Management – Risk Assessment Techniques

- AS IEC 61882 – Hazard and Operability Studies (HAZOP studies)

- ISO5048 Continuous Mechanical Handling Equipment – Belt Conveyors with Carrying Idlers

- CEMA (Conveyor Equipment Manufacturers Association) Calculations

Call Us Now For

- Bulk material characterisation and testing program planning and management

- Complete engineering and design including expansions and modifications

- Bid Packages, Project and Equipment Specifications and Project Estimating

- On-site Operational and Safety Audits, Inspections Services, Safety and Condition Reviews

- Problem Solving, System Repair, and Reconditioning Recommendations

- Structural, Mechanical and Electrical Inspections

- Troubleshooting and Diagnosis of issues including Tracking and Misalignment, Spillage, Dust generation and Dynamic issues which include stopping and starting.

Some Of Our Work

LARGE CONVEYOR SYSTEM

We have experience in working on the design and engineering of Large Conveyor system, with Belts up to 2m wide, 9,000t/hr and multiple MW drives.

We can engineer conveyor solutions that take into account the unique dynamic properties of long overland, high volume and steep angle conveying systems including inertia management and stopping and starting.

SMALL CONVEYOR SYSTEM

Small conveyor systems, including those handing Ores, Scatts, Concentrates, Samples, Tails and Residues are all engineered to the same recognised safety and operational standards.

CONVEYOR SAFETY AND OPERATIONAL AUDITING

Three decades of working on conveyor systems allows us to quickly carry out Conveyor Safety Audits against AS4024 and the Mining Acts and Regulations relevant to your site. We record all non-conformances and other areas of concern, undertake a risk assessment to assist you in prioritising any rectifications works or improvements.

We can undertake Mechanical, Structural and Electrical Inspections of your processing plant and will make sensible recommendations based on our finding and your goals.